MANUFACTURING

Panel Furniture Production

We have introduced advanced automatic production lines from Germany and Italy to achieve digitalized production. The German HOMAG automatic sawing machine and HOMAG CNC machining center precisely control the entire process, achieving a processing accuracy of ±0.1mm.

Additionally, German laser edge banding techniques improve efficiency, enhance aesthetics, and reduce pollution.

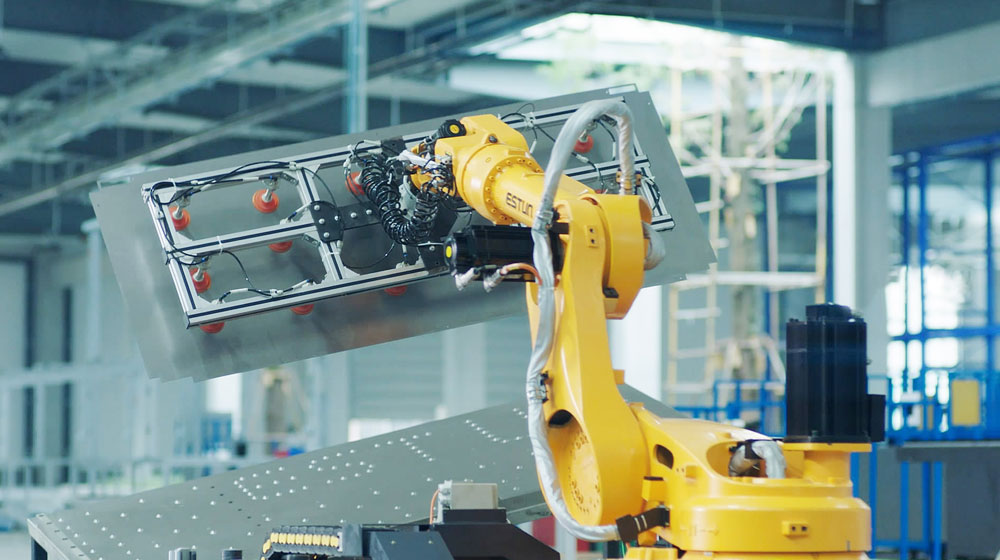

Steel Furniture Production

The combination of "intelligent control" and "resilient production" enables us to create steel products that fit into various spaces seamlessly. The Salvagnini machine imported from Italy ensures that the bending parts are stable and visually appealing.

For painting, we have implemented the German Wagner painting robot to provide superior quality and lower energy consumption.

Chair Production

We maintain strict control over the entire chair production process, with products certified by and follow BIFMA/GREENGUARD policies. Automatic sawing and cutting equipment significantly enhance efficiency and accuracy.

Automated drilling and riveting workstations also utilize robots to ensure precise drilling positions, sizes, and angles in the seat panels.

Sofa Production

Sunon adopts a JIT (Just-in-time) production mode to streamline management processes. Our bright and spacious workshops provide our employees a healthy, comfortable, and safe working environment.

Each type of sofa undergoes initial crafting of interior frames by experienced carpenters, referencing detailed process drawings. The use of Durkopp stitching techniques ensures neat and uniformly distributed stitches.